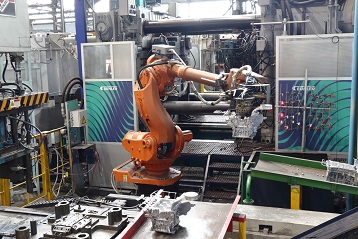

JAll latest machines are completely integrated cells with robotic extraction, auto- sprayers, dosing furnaces, integrated trimming presses and real time controls. This ensures high productivity, casting integrity and product reliability throughout the life of the equipment. These machines are capable of storing process parameter data of every shot ensuring full traceability of parameters in the event of a defective part. With 50 machines installed, Jaya Hind Industries is having capacity to manufacture 30,000 T of casting per annum.

Apart from die casting, downstream processes like trimming, shot blasting, vibro-finishing, machining, leakage testing and high pressure washing & drying make the product perfect for critical application in engines and transmissions.